LEEBOY

Our customers are accustomed to receiving the stability and experience that corresponds with our company’s reputable 60 year history.

Asphalt Paving Tools and Equipment

Explore LeeBoy Products

- Asphalt Pavers

- Brooms

- Chip Spreaders

- Distributors

- Electric Products

- Force Feed Loaders

- Hot Box

- Motor Graders

- Patchers

- Plate Compactor

- Road Wideners

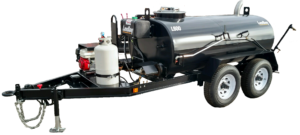

- Tack Tanks

-

-

-

6150

- Tier 4 Final – 74 hp (55 kw) @ 2,200 rpm

- Weight (with screed): 17,550 lbs

- Paving Widths Variable Up To 15’

-

7000C

- Tier 4 Final – 64 hp (48 kw) @ 2,400 rpm

- Weight (with screed): 13,000 lbs

- Paving Widths Variable Up To 13’

-

-

-

-

8520C

- 125 HP (93 kW) @ 2,200 rpm

- Weight (with screed): 21,400 lbs. | 22,100 lbs. (with HD Pro Screed)

- Paving Widths Variable Up To 15’ | Paving Widths Variable Up To 15’ 6” (with HD Pro Screed)

-

8520C Electric

- General Motors 48kW battery and battery management system

- Weight (with screed): 22,000 lbs.

- Paving Widths Variable Up To 15’

-

-

8616D

- 127 hp (95 kw) @ 2,300 rpm

- Weight (with screed): 23,450 lbs

- Paving Widths Variable Up To 15’ 6″

-

-

8680

- Tier 4 Final – 210hp (157 kW)

- Weight (with screed): 28,850 lbs

- Paving Widths Variable Up To 15’ 6″ with HD PRO screed

-

-

RB50

- Center-Mount Brush Location

- Tier 4 Final – 74 hp (55 kw) @ 2,500 RPM

- Weight: 5,510 lbs w/o water

-

-

Electric RB50

- Center-Mount Brush Location

- Drive System -General Motors 48kW battery and battery management system

- Weight: 5,510 lbs w/o water

-

Electric RB50

- Center-Mount Brush Location

- Drive System -General Motors 48kW battery and battery management system

- Weight: 5,510 lbs w/o water

-

8520C Electric

- General Motors 48kW battery and battery management system

- Weight (with screed): 22,000 lbs.

- Paving Widths Variable Up To 15’

Made in the USA

Trust LeeBoy

Our customers are accustomed to receiving the stability and experience that corresponds with our company’s reputable 55+ year history. Made in the USA, our ISO-certified manufacturing is evidence of our dedication to quality and our commitment to provide the absolute best equipment solutions.

Let’s protect our future together

LeeBoy’s vision statement stresses the importance of corporate and environmental responsibility. By adopting best practices and industry standards, including ISO-9001, we are committed to engineering dependable equipment for the paving contractor while demonstrating the utmost respect for our human and natural resources.